Predictive monitoring of electric motors with ADI OtoSense smart sensors

ADI OtoSense's Smart Sensor for Electric Motors (SMS) is a complete hardware and software solution based on Artificial Intelligence (AI) for condition-based monitoring and predictive maintenance of industrial electric motors. It monitors the condition of electric motors by combining the best detection technologies with state-of-the-art data analysis.

The solution consists of a hardware and software subsystem that includes a cloud platform, web and mobile application. An AI algorithm for motor fault diagnosis based on machine learning is implemented on the cloud platform. The figure below shows a diagram of the ADI OtoSense SMS system.

The ADI OtoSense SMS sensor integrates several high-performance sensors developed by ADI, including:

- Two ADXL1002 low-noise, high-frequency MEMS accelerometers for vibration detection in the X and Z axes.

- Two high-precision 16-bit digital temperature sensors ADT7420 for motor housing and ambient temperature detection.

- A magnetic field sensor for detecting motor speed and diagnosing motor electrical faults.

In addition to the sensors, the SMS also has a WiFi processor for collecting and packaging data for transfer via 2.4 GHz WiFi.

ADI OtoSense's SMS sensor is a market-leading solution for detecting and interpreting machine data. The following table shows the most common engine faults that the SMS sensor can diagnose and predict:

Table 1. Electric motor faults that the ADI OtoSense SMS intelligent sensor can diagnose and predict

Motor fault | Type of fault | Description | Example |

|---|---|---|---|

| Power system | Electrical | Problems in all three phases of the power supply, which can lead to unbalanced motor current | Lost phase |

| Stator winding | Electrical | Problems in one of the motor phases, which can lead to unbalanced motor currents | Short circuit in the coil |

| Rotor | Electrical | Problems related to the rotor bars or short-circuit ring | Broken rotor bar |

| Axle unbalance | Electromechanical | Uneven mass distribution, causing the center of gravity to move away from the center of rotation | Rotor bending |

| Eccentricity | Mechanical | Concentricity problem between rotor and stator, which can be caused by a bent rotor shaft or improper bearing installation | Bent shaft Improper bearing installation |

| Mechanical bearing | Mechanical | Mechanical stress or contamination leading to small cracks or defects occurring in the bearing, creating vibration problems | Corrosion |

| Misalignment | Mechanical | Occurs when two rotating shafts (motor and load) are not aligned, creating external misalignment | Angular or parallel misalignment |

| Problems with fastening or cushions | Mechanical | Looseness or instability that occurs when the engine base (or cushions) is not properly tightened | Engine poorly fixed to base frame |

| Cooling | Temperature | Problems with fans attached to the shaft or connected externally to the motor | Obstruction of the fan cover |

| General vibration | Performance | General increase in vibration. Indicates potential systemic problems. | Mechanical failures Decreased efficiency and increased energy consumption |

Electric Motor Operating Efficiency with ADI OtoSense SMS

Proper maintenance helps to achieve maximum economic profitability for companies, as the occurrence of motor failures is reduced and unscheduled downtime can be avoided. In addition, motor efficiency plays a key role in reducing operating costs, since a high-efficiency motor consumes less electricity than a motor with standard efficiency to deliver the same power.

Studies have been carried out to determine the extent to which the machine's efficiency is compromised by the presence of different types of faults. Specifically, the following types of faults: rotor faults, asymmetries in the stator windings, faults in the insulation system, unbalance/ misalignment and faults in the ventilation system.

Optimum motor operating efficiency by ADI OtoSense SMS

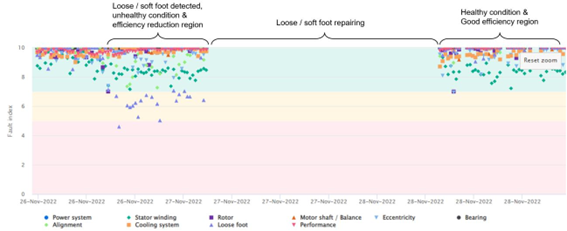

The figure above shows the optimization of motor operating efficiency with ADI OtoSense SMS sensor. The cloud platform provides unparalleled information on the engine's operating conditions and maintenance needs.

Thanks to the proprietary ADI OtoSense SMS predictive maintenance analysis, users can identify the 9 most common engine faults at an early stage and remedy the faults before they affect engine operation. For each engine fault, a Fault Score Index (FSI) is calculated to represent the severity of the engine faults.

The FSI is a value between 0 and 10. The FSI number above '7' means that the engine is in good condition. The FSI number between 5 and 7 indicates that an engine fault has been found at an early stage and a low severity WARNING notification will be delivered to the user by e-mail. An engine in WARNING status can still operate normally for a certain period of time; however, as the engine is not in healthy status, the engine's operating efficiency is degraded.

The figure below shows an example where a loose motor foot is detected early, and a WARNING notification is issued. When the user receives a notification, rapid repair action is recommended to bring the motor's operation back to optimum condition so that the motor can continue running at high efficiency.

Example showing how ADI OtoSense's SMS sensor keeps the motor running at high efficiency.

Do you want all these advantages in predictive monitoring of your motors? Contact us and talk to our experts!